News

The importance of energy-saving in dryers cannot be overlooked

Author:Editor:adminHits:152 Date:2025-07-21

Question: Many people think that air compressors consume electricity, while dryers basically don't use electricity. So what exactly does the dryer save energy for?

Question: Many people think that air compressors consume electricity, while dryers basically don't use electricity. So what exactly does the dryer save energy for?

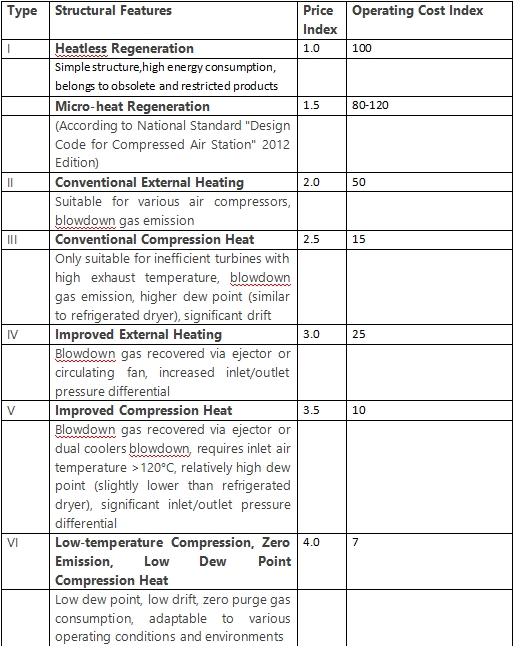

Answer: The adsorption dryer is a device with low purchase cost but high operating cost and high energy consumption. Depending on its energy consumption quality and conversion efficiency, it is classified into four generations of models (as shown in the table below)

Answer: The adsorption dryer is a device with low purchase cost but high operating cost and high energy consumption. Depending on its energy consumption quality and conversion efficiency, it is classified into four generations of models (as shown in the table below)

It is well known that the efficiency of converting thermal energy into electrical energy is less than 50%, and the efficiency of converting electrical energy into useful expansion work is less than 30%, and even lower. Therefore, the upgrading and replacement of adsorption dryers are carried out with the aim of using less gas or even no gas at all.

Question 2: Everyone is increasingly focusing on energy conservation. Compared to the past, how are the designs and manufacturing processes of our dryers different now? Please briefly explain in terms of the product.

Question 2: Everyone is increasingly focusing on energy conservation. Compared to the past, how are the designs and manufacturing processes of our dryers different now? Please briefly explain in terms of the product. Answer 2: Once the first question is clarified, the second question will be easily solved. The national standard "Design Specifications for Compressed Air Stations" limits the high-energy consumption of the first-generation machines to less than 20 m³. It recommends using heat-recovery regeneration. When using centrifugal machines and oil-free screw machines, heat recovery (waste heat) regeneration should be given priority. However, it also reminds the design and selection personnel to pay attention that traditional waste heat regeneration dryers are only applicable to the application range of refrigerated dryers or slightly lower than the dew point of refrigerated dryers. That is, traditional waste heat regeneration dryers cannot meet the basic indicators of other adsorption dryers with a pressure dew point of -20℃.

Answer 2: Once the first question is clarified, the second question will be easily solved. The national standard "Design Specifications for Compressed Air Stations" limits the high-energy consumption of the first-generation machines to less than 20 m³. It recommends using heat-recovery regeneration. When using centrifugal machines and oil-free screw machines, heat recovery (waste heat) regeneration should be given priority. However, it also reminds the design and selection personnel to pay attention that traditional waste heat regeneration dryers are only applicable to the application range of refrigerated dryers or slightly lower than the dew point of refrigerated dryers. That is, traditional waste heat regeneration dryers cannot meet the basic indicators of other adsorption dryers with a pressure dew point of -20℃. Question 3: In the air compressor industry, we pursue the so-called cost-effectiveness. Then, how can the dryer products demonstrate their cost-effectiveness?

Question 3: In the air compressor industry, we pursue the so-called cost-effectiveness. Then, how can the dryer products demonstrate their cost-effectiveness? Answer 3: Traditional adsorption dryers are a typical type of low-cost but high-energy-consuming equipment. During their entire lifespan (twenty years), their purchase cost only accounts for 1.5% to 3%, maintenance costs are only 1.5% to 3%, while operating costs are as high as approximately 95%. In recent years, LCC (Life Cycle Cost, a cost assessment for the entire product life cycle, see search on Baidu) has become popular, representing a new trend in cost evaluation. The author has presented several cases. When conducting LCC evaluations between the third and fourth generation machines and the first generation machine, for every increase of 10,000 yuan in purchase price, the total LCC cost can be reduced by approximately 1 million to 1.5 million yuan. Therefore, in many occasions, the author has proposed that the current bidding system is like a balance scale that weighs sesame seeds but loses a watermelon in the field. In essence, it is a waste of the evaluation expert resources and a disregard for the value of experts.

Answer 3: Traditional adsorption dryers are a typical type of low-cost but high-energy-consuming equipment. During their entire lifespan (twenty years), their purchase cost only accounts for 1.5% to 3%, maintenance costs are only 1.5% to 3%, while operating costs are as high as approximately 95%. In recent years, LCC (Life Cycle Cost, a cost assessment for the entire product life cycle, see search on Baidu) has become popular, representing a new trend in cost evaluation. The author has presented several cases. When conducting LCC evaluations between the third and fourth generation machines and the first generation machine, for every increase of 10,000 yuan in purchase price, the total LCC cost can be reduced by approximately 1 million to 1.5 million yuan. Therefore, in many occasions, the author has proposed that the current bidding system is like a balance scale that weighs sesame seeds but loses a watermelon in the field. In essence, it is a waste of the evaluation expert resources and a disregard for the value of experts.